Wet Dust Collector

Wet Dust Collector Systems

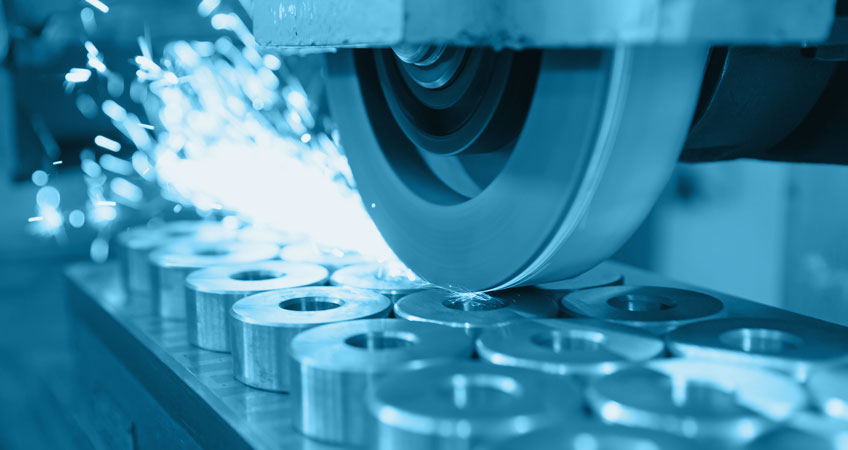

Wet Dust Collectors are best suited for pollutants which are difficult to filter using other conventional filtration methods such as bag house/cartridge filters/conventional Dust Collector or Electrostatic filtration. The system is available with additional attachment of recirculating water for specific processes like Shot blasting and many others.

Applications

- Shot Blasting

- and many more

Benefits

Effective solution

for pollutants which are difficult to filter using conventional filters

Assured safety

for applications with high risk of fire

Easy capture & filtration

ease of extraction / capture and filtration

Cost effective solution

for pollutants generated during processes such as shot blasting

Wet Dust Collector Risk-Free

Wet Dust Collector Risk-Free

Wet Dust Collector Risk-Free & Economical Solution

Wet dust collector from SFS is a proven solution to eliminate all the problems faced due to the use of a conventional dust collector system in process with a high risk of fire.

- Fire damages to filters

- Damage to equipment and property

- Loss of production hours/ days

- Loss of credibility and reputation

- Increase safety risks

Download brochures