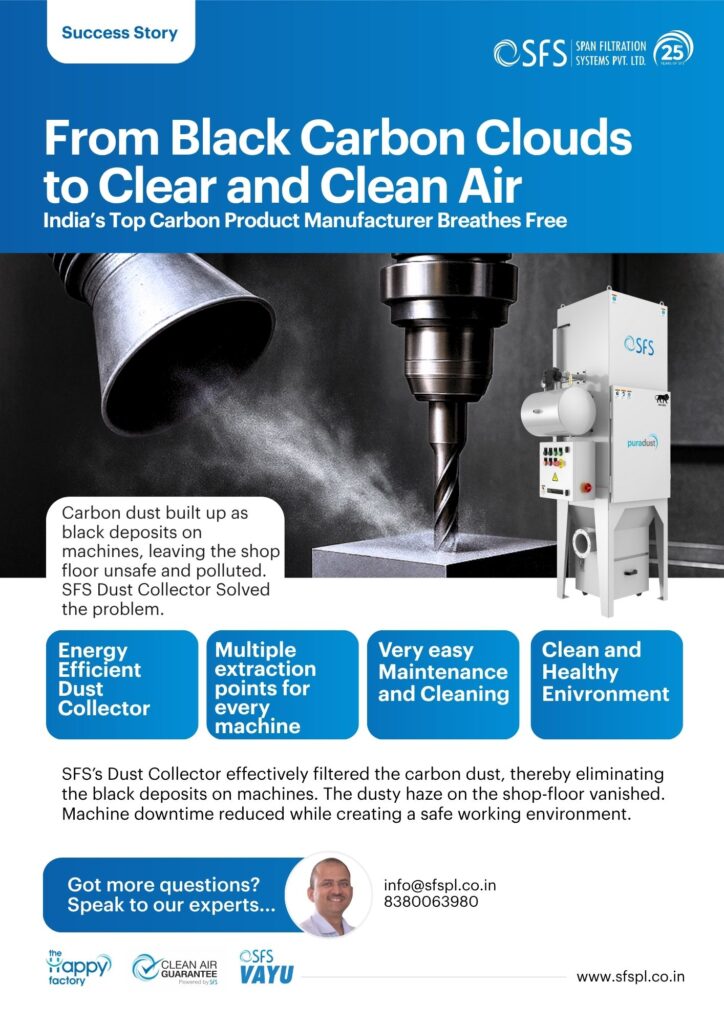

One of SFS’s clients, a manufacturer of carbon products such as carbon seals and carbon bearings, was facing significant air filtration challenges. Unlike graphite, carbon generates much finer and more porous dust particles, which are difficult to capture using conventional filtration systems. To effectively handle such fine dust, a larger filtration area is required.

Problem

- Dust type: Ultra-fine, porous carbon dust (finer and harder to trap than graphite).

- On-floor symptoms: Black deposits across the shop floor; visible particulates in air; frequent filter choking.

- Mix of cartridge-type and bag-type filters, undersized filtration area , poor suction.

- Health risk: Unhealthy environment for the operators.

- Root cause: System sized for a higher cloth ratio. For fine carbon particles the cloth ratio needed to be brought down, for more filter airflow.

After installing the SFS air filter, a single central system was catering to nearly 50 suction points, with each CNC turning machine connected at three points: one at the source, one at the bottom, and one at the enclosure. SFS provided a customized air filtration solution tailored to the client’s application. After implementation, the results were clear:

Result

- Air quality: The shop earlier coated in black dust, turned clean and visibly dust-free.

- Reliability: No more frequent choking of filters.

- Operations: improved machine uptime; safer, healthier environment for operators.

- User feedback: The team reported consistent performance and high satisfaction with the tailored setup.

The client expressed satisfaction with the solution, as it effectively resolved the long-standing dust issues and delivered consistent performance.