Welding Fume Extractor

SFS is leading the way as a manufacturer and supplier of a proven range of fume extractors for welding and other processes

‘purafume’ – the advanced range of fume extractors from SFS deliver superior filtration performance and air quality at your shopfloor. The fume extractors effectively filter fume from various types of manual and robotic welding processes. Centralised welding fume extractors are available on request. The SFS team conducts an in-depth study of your welding processes and shop-floor layout to create an optimum filtration solution that is customized to your needs. The duct and installation layouts are designed and mapped in advanced software to achieve desired flexibility and the best fume filtration performance.

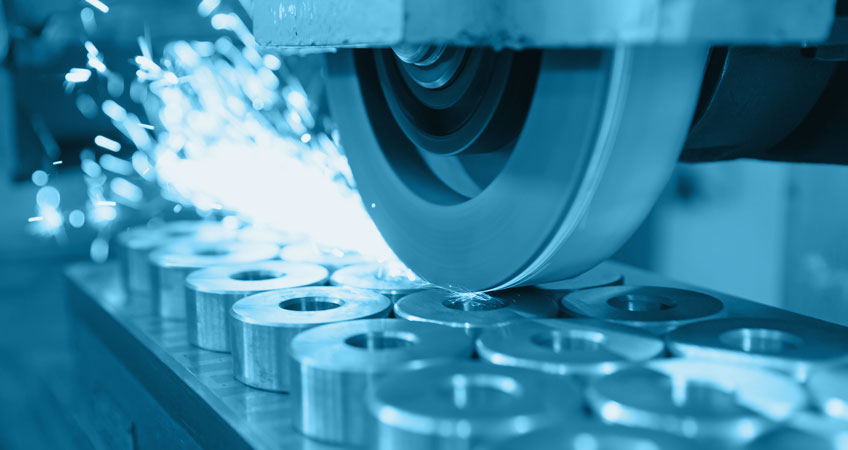

Applications

Standalone & Centralised Welding Fume Extractors for

- TIG Welding

- MIG Welding

- Laser Welding

- Robotic Welding and many more

Welding Fume Extraction Benefits

Key Features Welding Fume Extractor

-

Design

Compact design with wheels for ease of movement -

Filtration

Highly effective, efficient and consistent filtration -

Cleaning and maintenance

Built-In auto cleaning mechanism results in low maintenance -

User friendly accessories

Ease of operation due to availability of flexible suction arm -

Construction

Durable and robust construction

Welding Fume Extractor Working

FILTRATION

Effective suction hood design, efficient extraction leads to consistent and efficient filtration

MAINTENANCE

Inline cleaning leading to reduced maintenance

PROCUREMENT INSTALLATION & COMMISSIONING

Designed and manufactured in India under Make in India initiative

OPERATION

Energy efficient systems

Download brochure