Electrostatic Precipitator (ESP)

SFS is a manufacturer and supplier of Electrostatic Precipitators (ESPs) for effective filtration of smoke generated from manufacturing processes

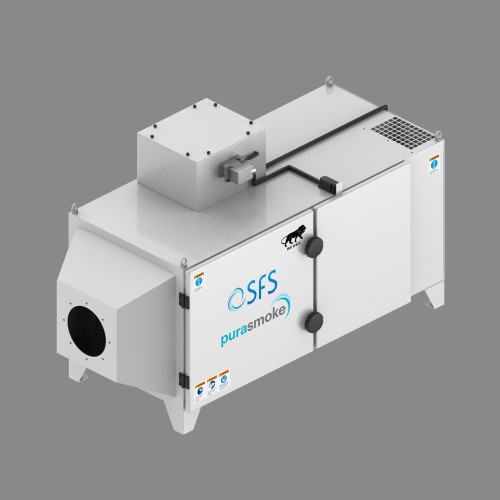

‘purasmoke’ –from SFS is a range of Electrostatic Precipitators (ESPs) for filtration of smoke and fumes that can serve your specific needs and meet the operational budgets. Smoke filtration is critical not just to worker’s health and safety, but even for smooth and efficient operation of the machining centres. The ESPs can be used as standalone filtration systems or centralised units for filtration from multiple stations. SFS’s years of expertise in filtration for neat oil machining and filtration of smoke and fumes generated during gear cutting, soldering fumes and other such manufacturing processes ensures that you always have a solution with superior performance that fits all your needs. Going beyond our role as ESP manufacturer and supplier, we offer reliable post-sales service and advise to obtain performance that delivers air quality on the shopfloor that exceeds your expectations.

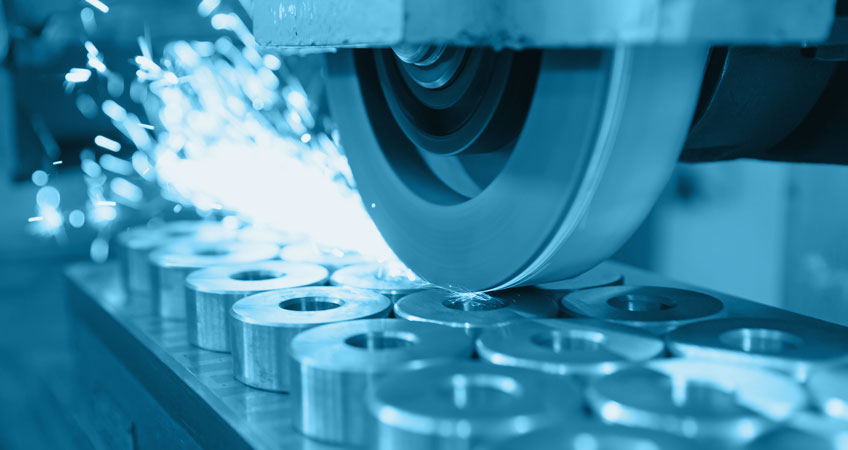

Electrostatic precipitator (ESPs) Applications

- Gear Cutting

- Straight Oil Machining

- Gear Hobbing

- Heat-treatment

- Grinding with Straight Oil

- Forging Operations and many more

Electrostatic Precipitator Key Features

-

Design

Compact design with smaller footprint -

Filtration

Highly effective, efficient and consistent filtration -

Easy cleaning

Easily removable and washable filters and stacks -

Construction

Durable and robust construction -

User friendly

VED Option available on request for energy saving -

Customisation

Customised Centralised option available on request

Smoke Extraction Systems - ESPs

FILTRATION

Effective suction hood design, efficient extraction leads to consistent and efficient filtration

MAINTENANCE

Easy availability and economical spares and consumables

PROCUREMENT INSTALLATION & COMMISSIONING

Designed and manufactured in India under Make in India initiative

OPERATION

Energy efficient systems

Complete solution to meet occupational, health and safety requirements

|

Oil smoke is hazardous and long term exposure can pose serious risks to life |

|

The dust and oil settles on the floor and machine surfaces and causes slippery surfaces affecting safety and performance |

|

Potential fire risks are created if oil smoke layers are formed in ventilation pipes, sensitive equipment like control panels etc. |

|

Cutting oil collected during oil smoke extraction can be made available for reuse |

|

Oil smoke levels beyond a certain level in the work environment violate pollution norms |

FILTRATION

Effective suction hood design, efficient extraction leads to consistent and efficient filtration

MAINTENANCE

Easy availability and economical spares and consumables

PROCUREMENT INSTALLATION & COMMISSIONING

Designed and manufactured in India under Make in India initiative

OPERATION

Energy efficient systems

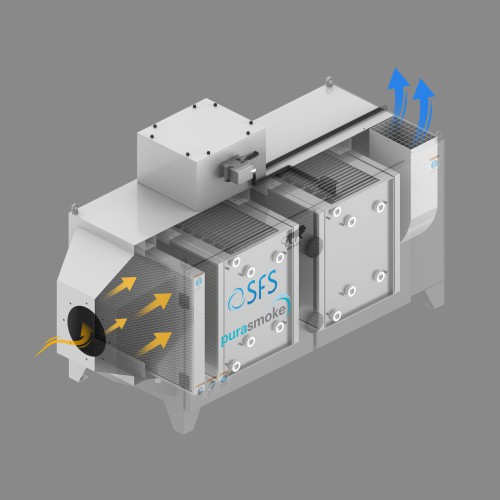

Electrostatic precipitator working principle involves ionization of air by applying high voltage to collect the fine soot or dust and oil particles in the smoke and thus filter the air. In an ESP, polluted air passes through two electrodes. These electrodes can be built in the form of bars or plates which are placed inside a pipe. The shape of the electrodes varies according to the type of ESP used.

One of these electrodes is charged with negative voltage which passes on the negative charge to particulates in the smoke passing through the unit. The other electrode situated further along the pipe is charged with positive voltage.

The negatively charged particles are attracted to this electrode and stick to it. The plates used in ESPs can be easily washed and cleaned for reuse.

ESP design

Factors important while designing an ESP

- The size and distributionof particles

- Gas flow rate

- Resistivity of the particles

- Gas temperature

- Chemistry of the particle

Download brochure