Dust Collector

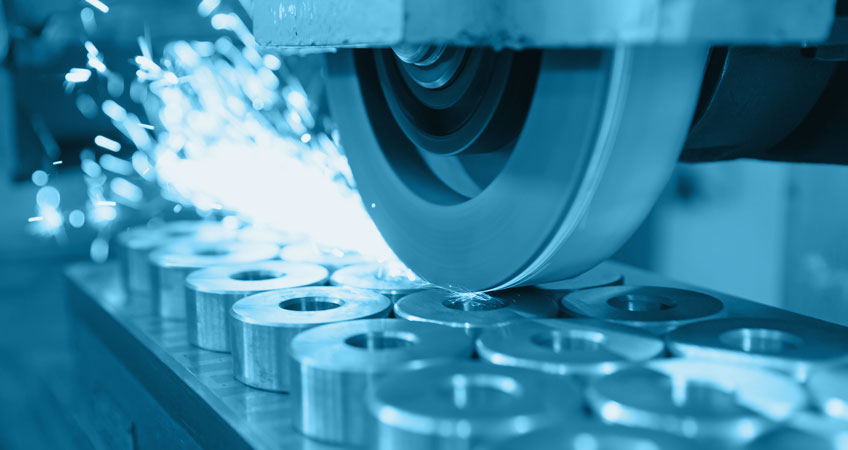

Dust Collector from SFS, India’s leading manufacturer and supplier of dust collector machine and dust collector systems for manufacturing process such as buffing, grinding, polishing dust to machining dust and many more...

puradust – the industrial dust collector and filtration systems from SFS enable effective filtration by capturing the dust generated at source from single or multiple workstations or machining centres. SFS also provides centralised dust collection systems for different applications on your shop floor.

An industrial dust collector captures the pollutants such as particulate matter, metal dust, buffing or grinding dust, polishing dust, superfinishing dust, rubber and various other types of dry dusts generated in the manufacturing processes. The dust collectors machine filter out the dust and release the clean air back into the shop floor or environment.

Applications

- Carbon Dust Collector

- Dust Collector for Grinding

- Buffing

- Dust Collector Machine for Industry

- Laser cutting dust collector

- Graphite Dust Collector

- Polishing Dust Collector, Dust Collector for Buffing Machine

- Bench/Tool Cutter

- Precast Slab Cutting

- Abrasive Cut-off machines

- Rubber Dust Collector

- Gold Dust Collector

Dust Collector Benefits

Prevent

Respiratory problems

Reduce

Accident risks

Reclaim

Valuable products

Increase

Productivity & equipment life

Low maintenance

With inline filter cleaning

Get reliable

Aand complete filtration

Efficient

Power usage

Designed for

Optimal use of space

Effective dust

capture with sturdy hoods

Clean

working environment

Dust Collector working principle

-

Performance

Designed for high filtration performance, safety and energy efficiency -

User friendly controls

Easy to use, well designed electrical controls and circuits -

Durable components

High quality and durable electrical components -

Built-to-last

Rugged, leak-proof construction -

Easy to clean

Inline cleaning of cartridge filters combined with easy filter access through front doors -

Detachable bin

Ergonomically designed dust bin with wheels for ease of dust removal -

Filter

Filter choke indication can be provided on request

Dust Collector Machine

FILTRATION

Effective suction hood design, efficient extraction leads to consistent and efficient filtration

MAINTENANCE

Inline cleaning leading to reduced maintenance

PROCUREMENT INSTALLATION & COMMISSIONING

Designed and manufactured in India under Make in India initiative

OPERATION

Energy efficient systems

Unbeatable performance at Unbelievably low cost of ownership

|

Harmful to operators, equipment and work environment |

|

Dust has a tendency to settle on the walls, floor etc. and increases maintenance |

|

Dust, especially fine dust, often finds its way into sensitive devices and can cause temporary or permanent damage |

FILTRATION

Effective suction hood design, efficient extraction leads to consistent and efficient filtration

MAINTENANCE

Inline cleaning leading to reduced maintenance

PROCUREMENT INSTALLATION & COMMISSIONING

Designed and manufactured in India under Make in India initiative

OPERATION

Energy efficient systems

Industrial dust collector manufacturers need to consider a number of factors when designing the industrial dust collection system. Four of the key factors that industrial dust collector manufacturers should consider include:

- Dust type

- Dust collection volume

- Air-to cloth ratio

- Air velocity

Ductwork: The size and complexity of the ductwork are determined by the size and complexity of the industrial dust collection system itself. Generally, industrial dust collector manufacturers try to limit the size of the system to ensure better efficiency.

Dust removal mechanism: Again, the dust loading rate and the type of dust being collected play a big role in design of the dust collector.

Explosion venting: If the dust in the manufacturing plant is combustible, the industrial dust collector manufacturers need to make provisions for venting of this dust without causing any fire incidents. This is generally done by integrating explosion vents or panels into the industrial dust collection system.

Download brochure