In recent years, almost every manufacturing industry has witnessed a significant surge in the use of laser technology for marking, welding, and engraving applications. Laser systems have become indispensable tools across various sectors due to their unmatched precision and versatility. From marking serial numbers on manufactured goods to intricately engraving detailed designs, and from laser welding micro-components to larger industrial tasks, the applications of laser technology continue to expand. This growing trend reflects a fundamental shift in how industries approach these processes, highlighting the need for efficient and tailored fume extraction solutions.

As the demand for laser-powered applications continues to rise, ensuring a clean and safe working environment through effective fume extraction becomes a crucial consideration. Let’s explore the essential aspects of selecting a laser fume extraction system to complement the increasing prevalence of laser-based applications.

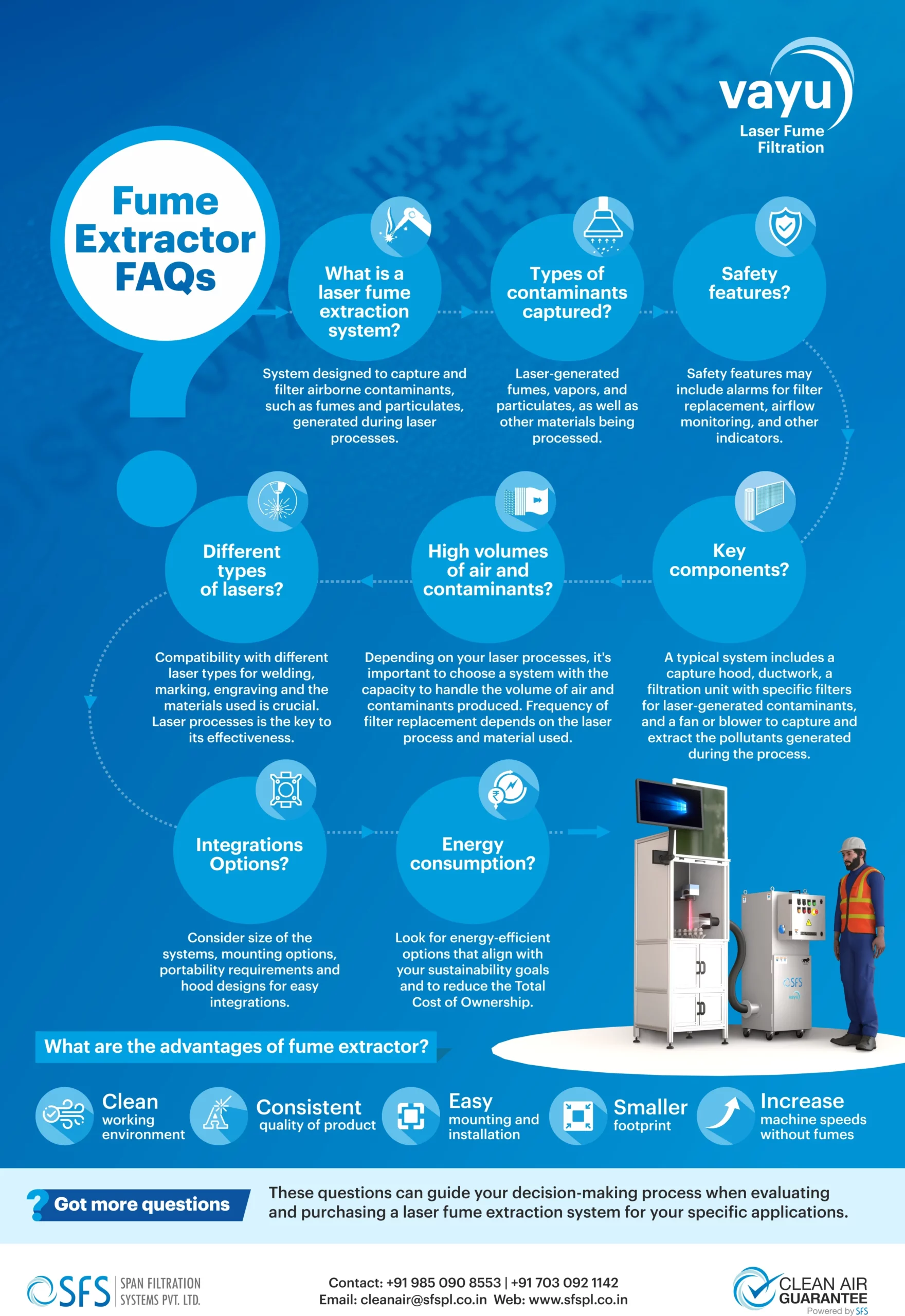

What is a laser fume extraction system, and why is it necessary in laser applications?

A laser fume extraction system is designed to capture and filter airborne contaminants, such as fumes and particulates, generated during laser processes. It helps maintain a clean and safe working environment.

What types of contaminants can laser fume extraction systems capture?

These systems are designed to capture various contaminants, including laser-generated fumes and particulates, depending on the materials being processed.

How does a laser fume extraction system work?

Laser fume extraction systems typically use a combination of fan and filters to capture and filter out fumes and particles produced during laser cutting, engraving, or marking processes.

What are the key components of a laser fume extraction system?

A typical system includes a capture hood, ductwork, a filtration unit with specific filters for laser-generated contaminants, and a fan or blower to capture and extract the pollutants generated during the process.

Can a laser fume extraction system be used with different types of lasers and materials?

Compatibility with different laser types and materials is crucial. Ensuring that the system can effectively capture and filter the specific contaminants generated in your laser processes is the key to its effectiveness.

What types of filters are used in laser fume extraction systems, and how often do they need to be replaced?

Different filters are designed to capture specific contaminants. Understanding the types of filters used and their replacement frequency is essential for ongoing maintenance. Specific filters for odour removal can be added on request. Frequency of filter replacement depends on the laser process and material used.

Is the system designed to handle high volumes of air and contaminants generated during intensive laser applications?

It is very important that manufacturers assess and understand the air volume and contaminant characteristics before purchasing the laser fume extractor. Depending on your laser processes, it’s important to choose a system with the capacity to handle the volume of air and contaminants produced.

What safety features are included in the laser fume extraction system?

Safety features may include alarms for filter replacement, airflow monitoring, and other indicators to ensure the system is operating effectively and safely.

Can the system be integrated with existing laser equipment or workstations?

Integration capabilities are important for seamless operation. Ensure that the system can be easily integrated into your current laser setup. Consider size of the systems, mounting options, portability requirements and hood designs for easy integrations.

What is the energy consumption of the laser fume extraction system?

Understanding the energy consumption helps assess the operational costs of the system over time. Look for energy-efficient options that align with your sustainability goals and to reduce the Total Cost of Ownership.

Does the manufacturer provide training and support for the installation and operation of the system?

Adequate training and ongoing support are essential. Ensure the filter manufacturer provides training for system installation, operation, and maintenance.

What is the warranty coverage for the laser fume extraction system, and what does it include?

Inquire about the warranty terms, including duration and coverage. Understanding the warranty details provides assurance and clarity on potential issues that may arise after purchase.

These questions can guide your decision-making process when evaluating and purchasing a laser fume extraction system for your specific applications.