Laser technology has become a ubiquitous tool across various industries, offering unparalleled precision and versatility. However, the process of laser cutting, engraving, or marking generates hazardous fumes and particulate matter. Laser fume extractors play a crucial role in mitigating these risks, making them an essential component in industrial settings.

This article highlights the importance of laser fume extractors, particularly in view of their various applications in the industry.

Protecting Health and Safety

The primary purpose of laser fume extractors is to safeguard the health and safety of workers. The fumes emitted during laser operations often contain harmful substances, including volatile organic compounds (VOCs) and microscopic particulates. Prolonged exposure to these pollutants can lead to respiratory problems, eye irritation, and other health issues. Laser fume extractors capture and filter these hazardous substances, ensuring clean air in the workspace and minimizing the risk of occupational health hazards.

Maintaining Equipment Efficiency

In addition to worker safety, laser fume extractors play a vital role in maintaining the efficiency and longevity of laser equipment. Fumes and particulates generated during laser processes can settle on sensitive components, such as optics and mirrors, leading to deterioration and reduced performance. By capturing these contaminants at the source, fume extractors help prevent damage to expensive laser equipment, reducing maintenance costs and downtime.

Compliance with Regulation

Industries must adhere to stringent environmental and occupational safety regulations. Laser fume extractors assist businesses in meeting these requirements. They help control and minimize emissions of hazardous substances, ensuring compliance with local, regional, and national regulations. By investing in high-quality fume extraction systems, companies can avoid penalties, legal issues, and reputational damage associated with non-compliance.

Laser Applications Across Industries

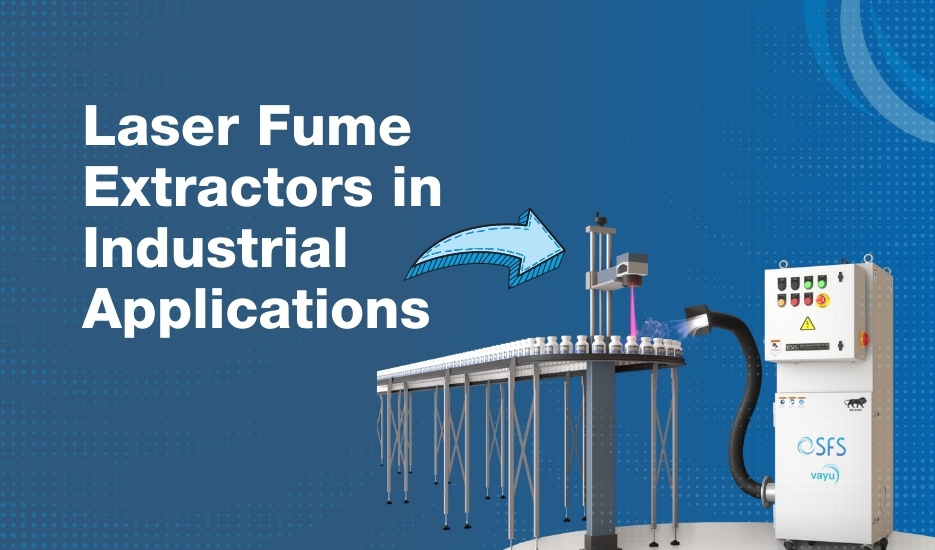

Laser technology finds applications in various industries, including manufacturing, automotive, aerospace, healthcare, and electronics. Consequently, laser fume extractors are essential across these sectors. Whether it’s laser cutting metal, engraving plastic, or marking medical devices, the fume extractors efficiently capture and filter the byproducts, ensuring a safe and clean working environment.

By prioritizing worker health and safety, maintaining equipment efficiency, and enabling regulatory compliance, laser fume extractors play a vital role in supporting the seamless integration of laser technology across diverse industries. Investing in reliable and efficient fume extraction systems is crucial for businesses aiming to maximize productivity, minimize health risks, and ensure a sustainable and safe working environment.

SFS is a leader in laser fume extractors. The Vayu-L Series of laser fume extractors is successfully used by several OEMs and end users to extract fumes and ensure clean, and healthy workplace. If you have a requirement for laser fume extractors, drop an email to cleanair@sfspl.co.in. We also offer fume extractors for laser welding, soldering, brazing and welding fumes.