Bar cutting processes are integral to various industries such as metal fabrication, construction, and manufacturing. These processes involve cutting metal bars into desired lengths or shapes, resulting in the generation of metal shavings, dust, and mist. While effective bar cutting techniques are crucial for productivity, it is equally important to prioritize cleanliness and maintain a safe and healthy work environment. In this blog post, we will explore the bar cutting process, highlight the need for mist collectors, and discuss how they contribute to keeping the shop floor clean.

Understanding pollutants in the Bar Cutting Process

Air Quality and Health

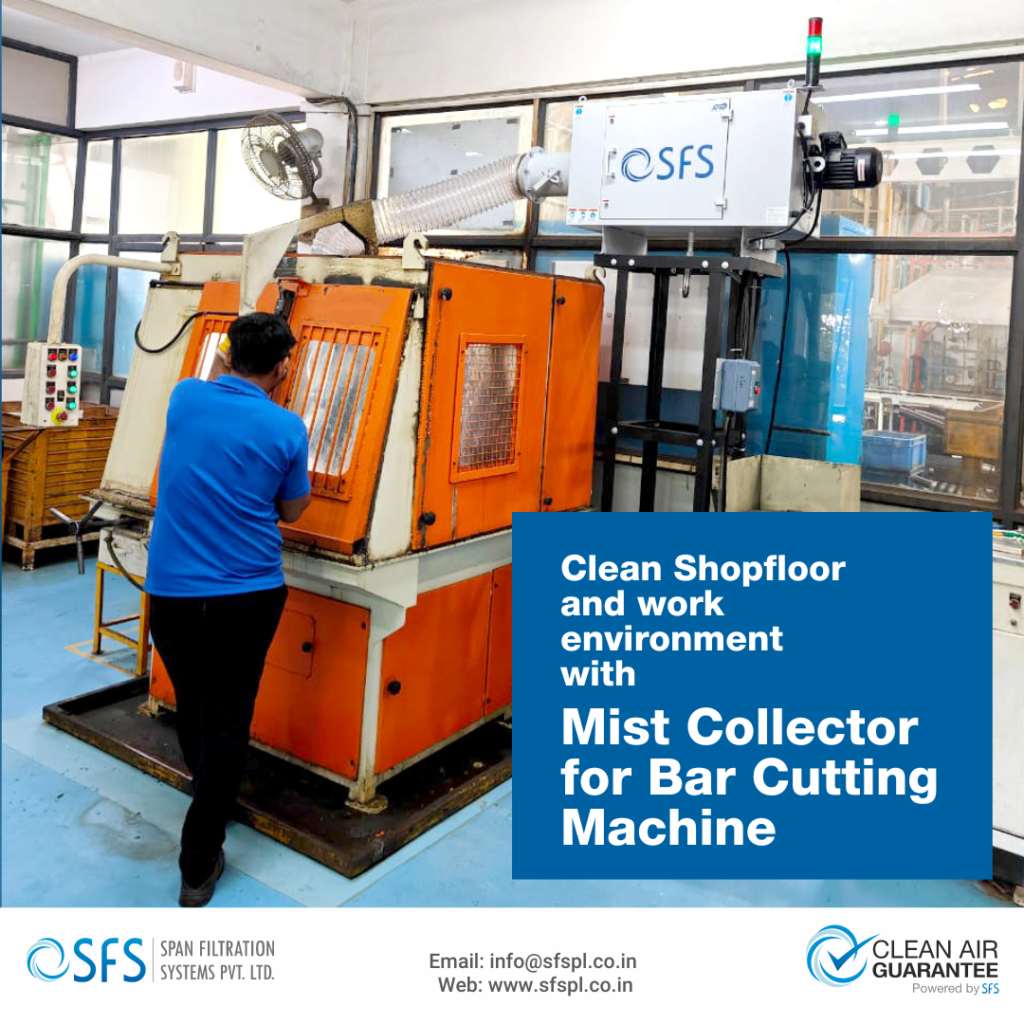

Mist collectors play a critical role in maintaining good indoor air quality by capturing and removing the mist generated during the cutting process. These mist particles can contain harmful substances, such as oil, coolant additives, and metal particulates. By eliminating these contaminants, mist collectors protect workers from respiratory issues and potential long-term health risks.

Cleanliness and Safety

Accumulated mist and airborne particles can settle on surfaces, machinery, and the shop floor, creating a slippery and hazardous environment. Mist collectors help prevent the buildup of these particles, ensuring a cleaner work area. This, in turn, reduces the risk of accidents, such as slips and falls.

Equipment Longevity

Metal shavings and mist can settle on machinery and equipment, potentially causing damage and reducing their lifespan. Mist collectors prevent the accumulation of these particles, protecting the cutting tools, machines, and other equipment from premature wear and tear, thus increasing their longevity.

Benefits of Mist Collectors

- Improved Efficiency: By effectively capturing and removing mist and airborne particles, mist collectors help maintain an unobstructed working environment. This enhances visibility, allowing workers to operate machinery and perform tasks more efficiently.

- Compliance with Regulations: Many jurisdictions have established regulations and standards to ensure worker safety and environmental protection. Implementing mist collectors helps businesses meet these requirements and maintain compliance with applicable regulations.

- Cost Savings: Proper filtration and removal of mist and particles minimize the need for frequent cleaning and maintenance of equipment and shop floors. This translates into cost savings in terms of reduced labor, cleaning supplies, and potential equipment repairs or replacements.