A reputed manufacturer of locks in India manufactured locks of international standard. It was imperative for the company that its commitment to making world class product also reflect in it its new production facility.

CHALLENGE

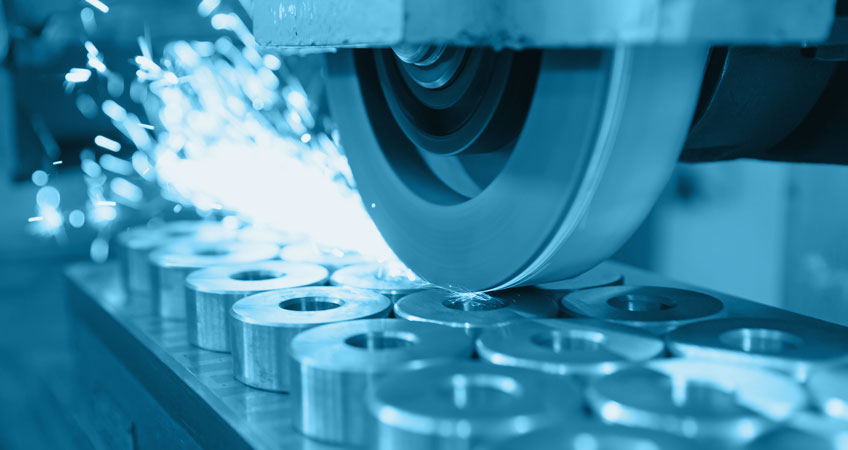

Brass, copper, stainless steel, mild steel and alloy buffing dust generated in the finishing line for locks was a major issue in the buffing shop. The buffing dust for each of the materials had a characteristic of their own. This created challenges in cleaning and filtration. The Client was looking for an efficient solution that could deliver an international standard of filtered air quality and ensure cleanliness in its rather compact buffing shop. The situation called for a lean but mean filtering machine.

SOLUTION AND BENEFITS

The DC 1600K C from SFS was chosen, and delivered a complete dust-free experience. The plug-and-play solution helped to reduce indirect costs incurred on cleaning of fine dust. The DC 1600K C helped the Client to build a healthy, happy and hygienic workplace in line with global health and safety standards right from the very first day of its installation.