Poor quality of soldering due to fumes in electrical wire harness manufacturing can lead to several issues that may impact the overall functionality and reliability of the wire harnesses.

Some specific issues caused by soldering fumes include:

1. Incomplete or Cold Solder Joints:

Soldering fumes can obstruct the soldering process, leading to incomplete or “cold” solder joints. Cold solder joints have poor electrical conductivity and mechanical strength, causing intermittent connections or complete failures.

2. Solder Bridging:

Excessive fumes can create an uneven distribution of solder, resulting in solder bridging between adjacent electrical connections. This can cause short circuits and malfunctioning of the wire harness.

3. Solder Splatter:

Fumes can lead to uneven heating of the solder, causing splatter that may land on adjacent electrical components or connections. This can create short circuits and damage electronic components.

4. Corrosion:

Residue from soldering fumes, such as flux or other contaminants, can cause corrosion on the solder joints or nearby components. Corrosion weakens the connections and can lead to electrical failures over time.

5. Reduced Adhesion:

Soldering fumes can interfere with the adhesion of solder to the wire strands or terminal surfaces, resulting in weak connections that may break under stress.

6. Contamination of Insulation:

Soldering fumes may deposit residue on wire insulation, compromising its dielectric properties and leading to insulation breakdown or reduced performance.

7. Electromagnetic Interference (EMI):

Poorly soldered connections due to fumes can increase the impedance of the wire harness, leading to EMI issues and signal interference in sensitive electronic systems.

8. Reduced Electrical Conductivity:

Incomplete soldering due to fumes can lead to high electrical resistance at the joints, affecting the overall electrical conductivity of the wire harness.

9. Reliability Issues:

Poor soldering quality caused by fumes can result in premature failures or performance issues in the wire harness, leading to increased maintenance costs and reduced product reliability.

10. Safety Hazards:

In extreme cases, poor soldering due to fumes can create safety hazards, such as short circuits or sparks, which may lead to electrical fires or accidents.

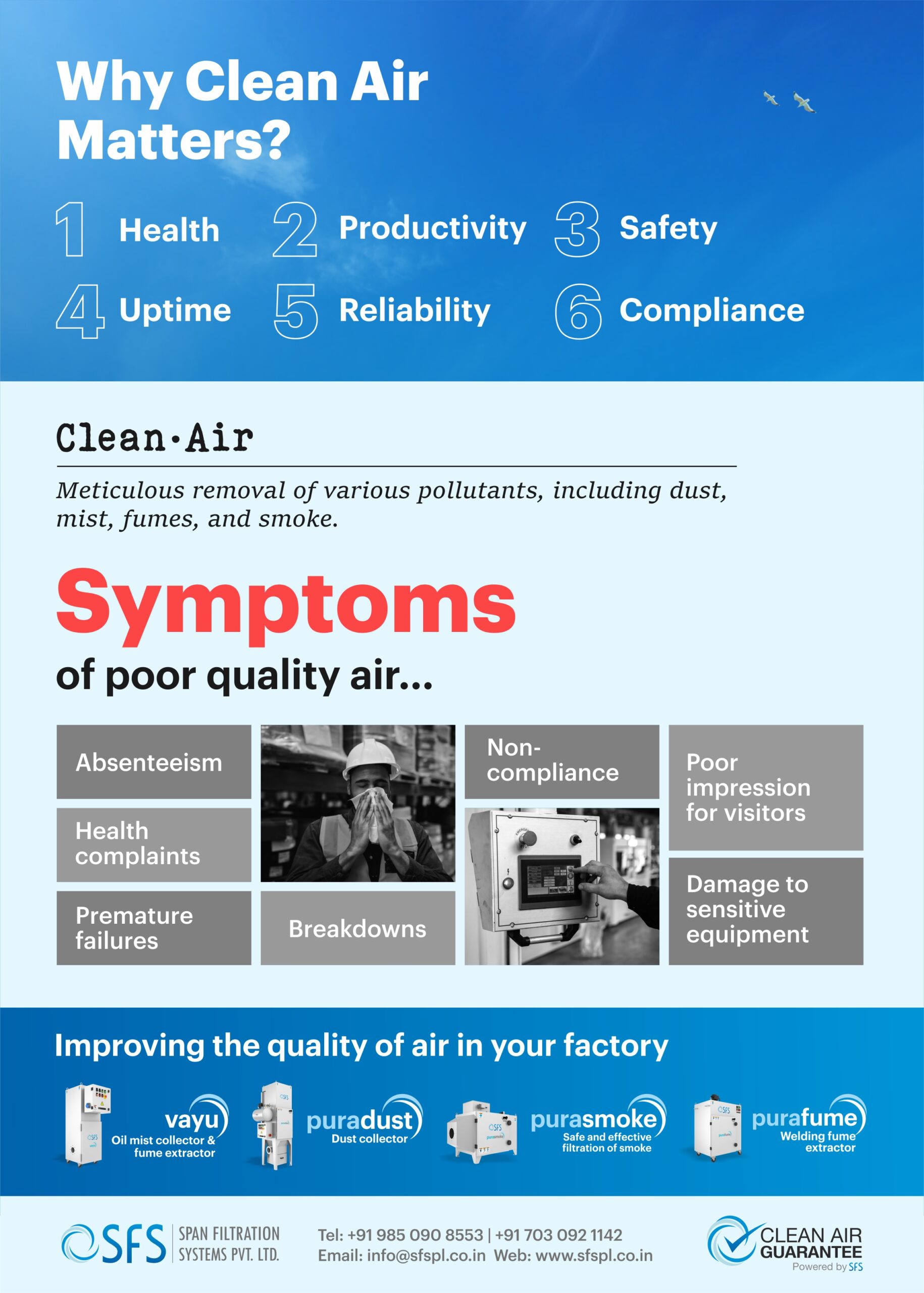

To avoid these issues, it is crucial to implement effective fume extraction systems and provide proper training to soldering operators. Maintaining a clean and fume-free work environment ensures high-quality soldering and reliable electrical wire harnesses.

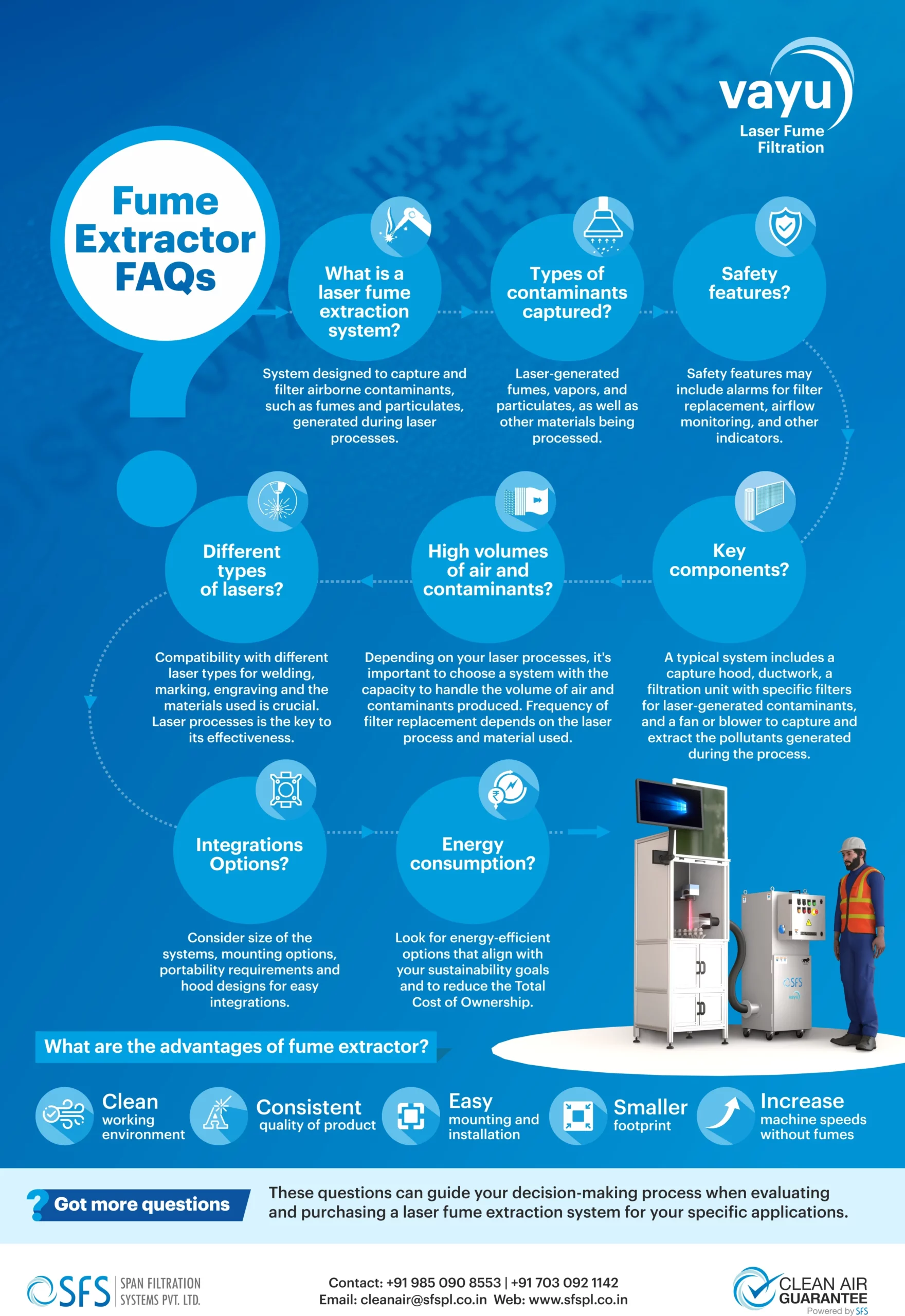

SFS has helped several electronics components manufacturers to overcome faults and reduce the risks related to soldering fumes. SFS’s Solutions are well proven to provide highly effective fume filtration for single or multiple soldering stations. Experts from SFS are always available to assist you at every step, from selecting the right filter to designing and implementing of fume filtration System. The experts have a deep understanding of the soldering process and help you resolve technical issues, and meet all the health and compliance standards required for soldering.

If you suspect that the fumes are affecting the soldering quality in your components, or impacting health of workers, do get in touch with us at cleanair@sfspl.co.in