Mist Collector

SFS is one of India’s fastest growing manufacturers of mist collector/mist filters for applications that need effective & efficient filtration of emulsion mist with economical investments.

Vayu – the industrial mist collector/mist filter series is ideal for filtration of emulsion mist from wet machining processes such as turning, milling, drilling, wet grinding and many others. The mist collectors are available as a single unit with direct mounting on the machining centres or can be used as a centralised mist collector for filtration of mist from multiple machining centres. SFS’s mist collectors are based on static media based filters and therefore come with several advantages over the conventional centrifugal mist collectors/ filters. The mist filters from SFS are designed for easy mounting, low maintenance and highly cost-effective operations with Built –in Filter clog signal.

Oil mist collection - Applications

- Oil mist collector for Turning

- Oil mist collector for Superfine machining

- Oil mist collector for Milling

- Oil mist collector for Grinding

- Oil mist collector for Finishing operations

- Oil mist collector for Super Finishing

Oil mist collector for CNC machines - Benefits

Prevent

Respiratory problems

Cut

Cleaning bills

Filtration

Without vibrations

Increase

Productivity & equipment life

Saves

Energy

Built-in

Filter clog signal

Easy to

Mount & install

Provides consistent

suction & filtration

Easy

Maintenance

Key Features of Oil mist filter

-

Filtration

Four-stage filtration with option of HEPA filter -

Air flow

Better air flow to energy consumption ratio than conventional Centrifugal Filters/Mist Collectors -

Filter Cassettes

Easy to remove & clean filter cassette slides - NO Vibrations!

-

Construction

Sturdy and durable construction - Built-In Filter clog signal

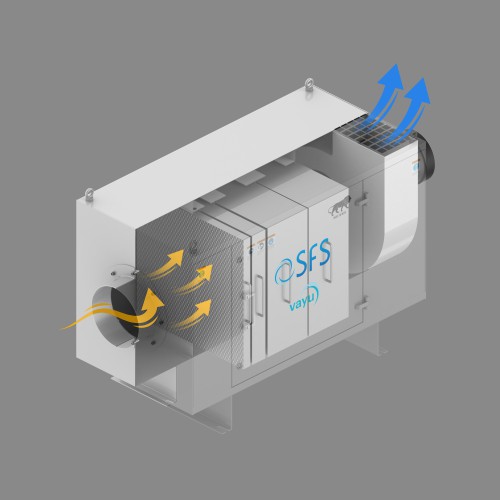

Oil mist collector working

FILTRATION

Effective suction hood design, efficient extraction leads to consistent and efficient filtration

MAINTENANCE

No vibrations or moving parts in the filter help to reduce maintenance

PROCUREMENT INSTALLATION & COMMISSIONING

Designed and manufactured in India under Make in India initiative

OPERATION

Energy efficient systems

Mist Free Assurance at Low Cost

The ideal choice for low-pressure emulsion mist

The VAYU Media Filters from SFS comes in two standard models to cater to full range of manufacturing processes with low-pressure emulsion mist generated from the coolant.

Mist Free Assurance at Low Cost

The contaminated air from the machining enclosure is extracted by an effective suction blower through four stage filtration. This ensure effective separation of fine particles by Inertial Impaction and separation by static media.

Why Mist Collector?

| Prevent Respiratory Problems |

| Cuts cleaning bills |

| Increases productivity and equipment life |

FILTRATION

Effective suction hood design, efficient extraction leads to consistent and efficient filtration

MAINTENANCE

No vibrations or moving parts in the filter help to reduce maintenance

PROCUREMENT INSTALLATION & COMMISSIONING

Designed and manufactured in India under Make in India initiative

OPERATION

Energy efficient systems

Unbeatable performance at

Unbelievably low cost of ownership

SFS has rich experience of providing dust collection solutions for automotive processes, composite dusts, welding smoke and many more. Our comprehensive range of highly reliable, durable and rugged dust collectors to keep your operations clean and smooth.

Our solutions are recognized for highly effective filtration across all kinds of environments starting from heavy loads of dust to thin dust collections or product reclaims.

Why Dust Collectors?

| Harmful to operators, equipment and work environment |

| Dust has a tendency to settle on the walls, floor etc. and increases maintenance |

| Dust, especially fine dust, often finds its way into sensitive devices and can cause temporary or permanent damage |

Download Oil Mist Collector Catalog (pdf)

Frequently Asked Questions

The VAYU series is an industrial mist collector/filter ideal for the effective & efficient filtration of emulsion mist generated from wet machining processes. It is specifically designed for emulsion mist produced by coolants during operations.

Unlike conventional centrifugal mist collectors, SFS’s VAYU series uses static media-based filters. This technology provides several advantages, including a better air flow to energy consumption ratio, lower energy consumption, built -in filter clog signal, consistent performance and operation with no vibrations.

Yes, the mist collectors offer flexible installation. They are available as a single unit for direct mounting on individual machining centers or can be configured as a centralized mist collector system to handle mist from multiple machines.

The key benefits are protecting operator health by preventing respiratory problems, reducing facility cleaning and maintenance bills, and increasing overall productivity and equipment life by keeping machines clean.

Maintenance is simplified with easy-to-remove and clean filter cassette slides. The unit also includes a built-in filter clog signal that provides timely alerts, ensuring uninterrupted performance and helping you plan maintenance.

The VAYU Mist Collector is designed for highly cost effective operations across its entire lifecycle. This is achieved through built -in filter clog signal, low maintenance needs, energy efficient operation (better airflow-to-energy ratio), and durable construction that ensures long-term reliability.

Success Stories

Frequently Asked Questions

What is the Airflow CMH of the mist collector?

Vayu 3- 400 CMH

Vayu 5 – 800 CMH

Vayu 9 – 1600 CMH

What type of media is used in the four-stage filtration system?

Stage 1&2 – pre-filter (Wiremesh Filter/ (Foam Filter)

Stage 3 – Primary filter (HDPE Filter)

Stage 4 – Secondary filter

What are the power consumption specifications for the filters?

Vayu 3- 0.112/0.15

Vayu 5- 0.37/0.5

Vayu 9- 0.75/ 10

How does the filter clog indicator help?

The Filter Clog Indicator helps operators monitor the condition of the filters at a glance. It utilizes a simple traffic light system to indicate whether the filters are clean, partially clogged, or completely blocked. Understanding these signals and acting promptly ensures the Vayu 3 unit runs efficiently, protects the machine, and maintains safe working conditions. Below is a guide to the meanings of each light and the corresponding actions required.

How does VFD help in energy savings?

What is the Maintenance period of the filter?

Are filtres washable?

Which filters are used in an air filtration machine?

Stage 1: Stage 1 Pre filter (Wiremesh Filter) is used to filter droplets or splashes of liquids.

Stage 2: Pre Filter (Foam Filter) is used to filter finer droplets of liquids which have been passed through the Wiremesh Filter

Stage 3: Stage 3 Primary Filter (HDPE Filter) is the main filter to carry out the filtration in Vayu 5/9 Filter Units. The filters are available in Varying Filtration Efficiencies, including EU5, EU7, and EU9. The filters supplied is based on optimum efficiency for the application. Usually, the filter configuration of Stage 3 HDPE EU7 is followed by Stage 4 HDPE EU9.